Visdamax Malaysia can supply a large variety of timber drying equipment ranging from forklift loaded kilns to truck loaded kilns, to high temperature and vacuum kilns. Controls for these kilns range from semi-automatic to fully automatic PLC or custom designed controllers. Coupled with the latest in timber drying technology: Load cells or moisture probes for timber moisture measurement, our kilns will satisfy your every requirement.

With over 30 years of experience in the timber drying business and with kiln installations over many parts of the world, we would like to welcome you to our world of timber drying equipment.

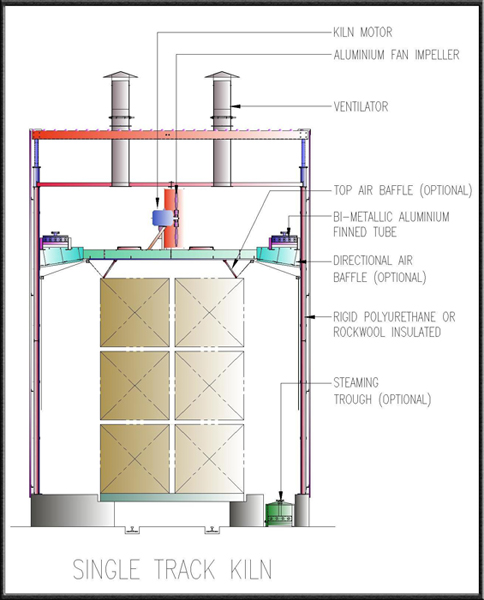

A Brief Description:

Single Track Loaded Kilns can come in a variety of equipment combination.

- Medium temperature kilns up to 90C.

- Loaded via bogie truck or a lift and transfer truck for large installations.

- Can be single or double ended.

- Heating medium can be steam, hot water, pressurized hot water or thermal oil.

Key Features & Advantages:

Some of the key features and possible configuration of our Single Track Loaded Kilns are:

- Panels shipped in modular pieces for easy assembly / installation at site.

- Panel frames made from aluminum and sheets from stainless steel ensuring long lasting life.

- Insulation made from rigid polyurethane. More efficient and longer lasting than rockwool.

- Stainless steel steaming troughs as an option for humidification and conditioning.

- Front, rear & top baffles to ensure no air bypass.

- Fully modulating control valves for heating, humidification, venting, spraying and fan controls.

- Inverters (Variable speed drives) for fans ensuring efficient energy usage.

- Cold water sprays or live steam sprays available upon request.

- Fully automated controls via PLC or standard controllers with data logging and remote access.

- KD motors are class H for better cooling and come with heaters to minimize condensation.

- Standard drying capacity is up to 60m3 (2" thick timber, 12 packs of 6m long)

These kilns can also be custom engineered to suit your specific drying capacities and design requirements. Please contact our staff or agents for more information.

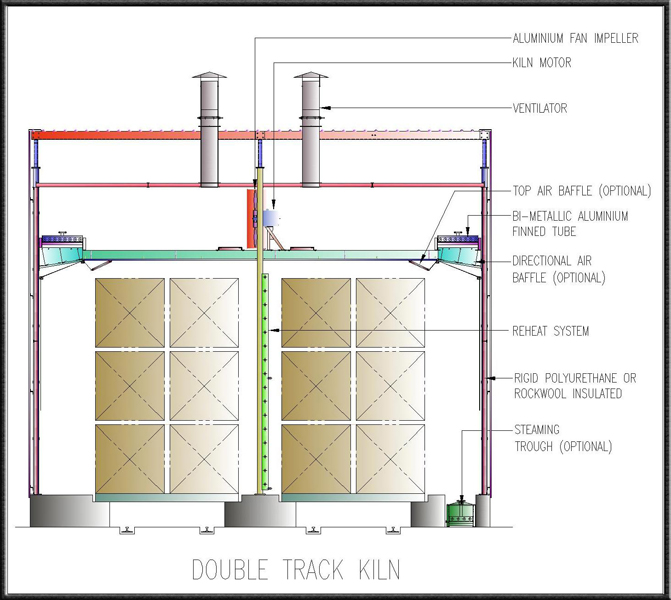

A Brief Description:

Double Track Loaded Kilns are very similar to single track loaded kilns except for the larger drying capacity. They can also come in a variety of equipment combination.

- Medium temperature kilns up to 90C.

- Loaded via bogie truck or a lift and transfer truck for large installations.

- Can be single or double ended.

- Heating medium can be steam, hot water, pressurized hot water or thermal oil.

Key Features & Advantages:

Most of the features for our Double Track Loaded Kilns are similar to the Single Track Kiln. Please refer to the features of the Single Track Kilns for more information. Only the additional features are listed below:

- Addition of an independant reheat system between the stacks to provide adequate heating.

- Single larger chamber saves up on structural cost minimizing capital investment.

- Standard drying capacity is up to 120m3 (2" thick timber, 24 packs of 6m long)

These kilns can also be custom engineered to suit your specific drying capacities and design requirements. Please contact our staff or agents for more information. The only drawback to such larger kiln chambers is the need to have a homogeneous charge. Will be less ideal for companies with many differnt types of timber to dry with small charges only.

Quick Jump:

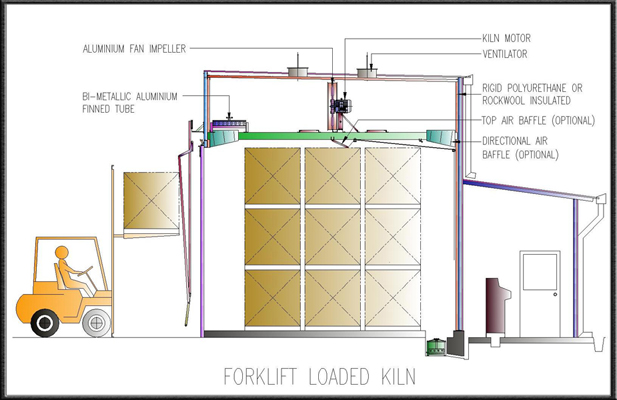

A Brief Description:

Forklift Loaded Kilns are generally used when larger drying capacities are required. They are more cost effective when compared with their counterpart the track loaded kilns. However, charge changes will require more time as the stack cannot be prebuilt then loaded in the drying chamber. They come with a variety of configurations and options:

- Medium temperature kilns up to 90C.

- Forklifts are required for loading timber stacks into the chamber.

- Heating medium can be steam, hot water, pressurized hot water or thermal oil.

Key Features & Advantages:

Most of the features for our Forklift Loaded Kilns are similar to the Single Track Kiln. Please refer to the features of the Single Track Kilns for more information. Only the additional features are listed below:

- Panels can be prefabricatd panels made from aluminum and stainless like the Single Track Kiln.

- Single larger chamber saves up on structural cost minimizing capital investment.

- Standard drying capacity ranges from 50m3 to 200m3 or larger (2" thick timber)

These kilns can also be custom engineered to suit your specific drying capacities and design requirements. Please contact our staff or agents for more information. The only drawback to such larger kiln chambers is the need to have a homogeneous charge. Will be less ideal for companies with many differnt types of timber to dry with small charges only.

Quick Jump:

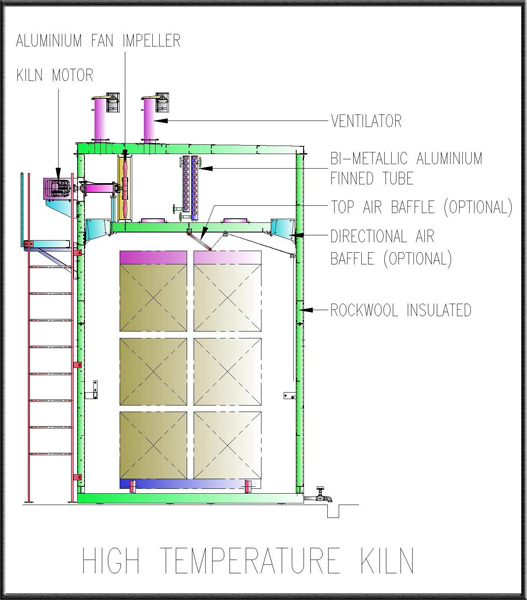

A Brief Description:

High Temperature Kilns are generally used when very quick drying throughput is required with quality being of secondary importance. High Temperture Kilns are predominantly used for softwoods like radiata pine etc. The High Temperature Kilns come in a variety of configurations and options:

- High temperatures ranging from 110C to 140C.

- Design is normally for bogie truck loaded and can be single or double ended.

- Heating medium is normally steam, high pressure hot water or thermal oil.

Key Features & Advantages:

Some key features of the High Temperature Kilns is listed below:

- Panels are prefabricated from steel structures with a complete internal stainless sheathing.

- Panels are modular in pices for easy site assembly / installation.

- Panels will be fully welded to prevent any leaks and can last for a very long time.

- Steaming troughs for humidification and conditioning can be supplied on request.

- External motors with couplings are used to minimize effects of heat.

- Restrain weights can be provided on request.

- Standard drying capacity ranges from 30m3 to 60m3 or larger (2" thick timber)

These kilns can also be custom engineered to suit your specific drying requirements. As our design is by modular prefabricated panels, requests for chambers to any specific size can be accommodated. Please contact our sales agents or stadd for more information.

Quick Jump:

A Brief Description:

Visdamax Malaysia have been building and supplying vacuum drying chambers to Japan since 2000. We have supplied over 30 vacuum chambers to Japan for drying of their 4" x 4" Japanese Ceder timber. However, in these instances, we have only ever supplied the equipment without the controls for these projects. Today we are conducting our own research into the viability of vaccum drying for the Malaysian hardwood timbers as well other hard wood or difficult to dry timbers.

We even have an experimental research vacuum drying chamber located in our factory for testing and research purposes. The most difficult aspect of vacuum drying is the schedules to be used for the timber. The schedule must be quick enough when compared to standard kiln for commercial viability as well being able to dry the timbers with minimal defects.

At present the controls for the vacuum dryer unit is by Logica with moisture and EMC probes. The controller is fully automated with data logging capabilities. As we are doing more research into the vacuum chamber, we are also developing our own software systems by using PLCs from Siemens, ABB or Allan Bradley.

The vacuum chambers that we have supplied to Japan vary in sizes from small cylindrical 10m3 chambers to rectangular driers in the range of 50m3. The cylindrical chambers are transportable entirely by container minimizing the amount of work required at site. The rectangular driers on the other hand are of the prefabricated panel design. The panels will be shipped to site for installation. The panels will need to be fully welded at site to ensure a proper vacuum seal.

The system can run on a a simple hot water circuit as the temperatures in the chamber only needs to go up to 80C for drying to occur.

For more information, please contact our local sales agents for more information.

Quick Jump:

Sample Timber Drier / Kiln Pictures |

|

| Track loaded (Lift & Transfer Truck System) in Malaysia. | |

| Track loaded (Lift & Transfer Truck System) in Malaysia. | |

| Track loaded (Lift & Transfer Truck System) in Siberia, Russia. (These are double track kilns) | |

| Internal look at the reheat system for a 500m3 double track loaded kiln, New Zealand. | |

| Forklift loaded kilns in Malaysia. | |

| Forklift loaded kilns in Japan. | |

| High temperature kiln in Japan. Small unit. | |

| High temperature kiln (blue) and medium temperature kiln (silver) in Australia. Each approximately 60m3. Bogie truck loaded. | |

| Small cylindrical vacuum dryer sold to Japan. | |

| Larger rectangular vacuum driers sold in Japan. | |

| The internal structure of an all stainless steel rectangular vacuum drier. Bogie truck are aluminum. | |

Quick Jump: